AlbertiniPackagingGroup

Making Responsible choices to minimize

environmental impact

GEOTHERMAL

PLANT

LED

ILLUMINATION

COMPANY CAR

FLEET

WASTE

DISPOSAL

One of our priorities is the focus on waste disposal and the recyclability of waste. We are very close to our objective of more than 90% recyclability of our production waste.

CERTIFICATIONS

GEOTHERMAL PLANT

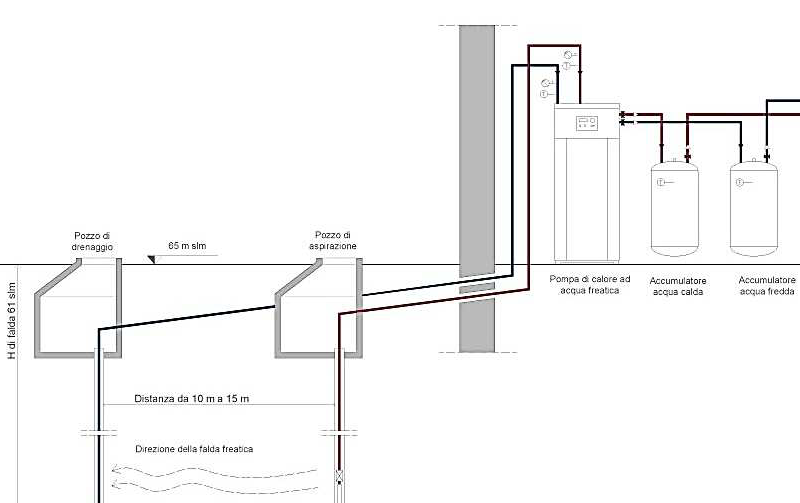

There has been a growing attention and a great interest on the geothermal resource as a source of renewable energy during the last few decades. The decision to focus on a renewable resource such as geothermal energy was undertaken with a special eye to environmental sustainability, contributing to the reduction of carbon dioxide emissions and fine dust deriving from air conditioning. According to the commitment made by most of the countries during the international Kyoto treaty in this branch, the use of low-depth geothermal energy was chosen in order to obtain sustainable resources both from an energy and environmental point of view.

“the use of underground water

is extremely ecological”

Plants using water to perform heat exchange in a direct way, taking water from the aquifer and re-introducing it into the same aquifer, are called open loop systems or forced convection systems. The potential for heating and/or cooling of groundwater is very high but is linked to the hydro geological characteristics of the area. Luckily, from this point of view the subsoil of the provincial territory is rich in water bodies that guarantee high productivity, especially those of fluvial and glacial nature.

Details on the re-entry conditions

A real protection of the environment passes through the correct planning of the plant, so that the groundwater collected from the subsoil and passed through the heat exchangers is returned to the ground without alterations. For the re-introduction of the water in the same aquifer it is necessary to respect different conditions, such as:

- Maximum allowed temperature for the returning water equal to 20 ° C

- Absence of chemical-bacteriological variation between the values measured in the withdrawn and in the discharged water

- No short or medium-term thermal short-circuiting

- Verification of the heat bubble width in the operating conditions

- Verification of the deformations induced locally on the stratum and possible failures or damage to the overlying and / or surrounding structures

- Performing at least one analysis per year on the withdrawal and re-entry water, using by analogy, the tabular limits of the discharge in the course of water

LED ILLUMINATION

The LED technology (Light-Emitting Diodes) represents the evolution of lighting, in which the light’s generation is obtained by using semiconductors instead of using a filament or a gas. LED lighting has several advantages over other lighting technologies available on the market:

- important energy savings

- longer life (average life: 50,000 hours)

- high luminous efficiency (120 lm/W compared to 13, 16 and 50 of incandescent, halogen and fluorescent lamps)

- it does not emit warm light, thus optimizing efficiency

- maintenance not necessary

- silica powder content and not harmful substances

- total absence of light pollution

- minimization of UV and IR emissions

The LED technology (Light-Emitting Diodes) represents the evolution of lighting, in which the light’s generation is obtained by using semiconductors instead of using a filament or a gas. LED lighting has several advantages over other lighting technologies available on the market:

- important energy savings

- longer life (average life: 50,000 hours)

- high luminous efficiency (120 lm/W compared to 13, 16 and 50 of incandescent, halogen and fluorescent lamps)

- it does not emit warm light, thus optimizing efficiency

- maintenance not necessary

- silica powder content and not harmful substances

- total absence of light pollution

- minimization of UV and IR emissions

COMPANY CAR FLEET

WASTE DISPOSAL

One of our priorities is the focus on waste disposal and the recyclability of waste. We are very close to our objective of more than 90% recyclability of our production waste.

CERTIFICATIONS

The APG Cosmetic Division has implemented an Environmental Management System conforming with the international standard UNI EN ISO 14001 which is committed to promoting any direct action to protect the respect for the environment. For this purpose, specific environmental programs are defined and activated for the optimal use of resources such as:

- Water management

- Atmospheric emissions

- Promote energy savings

- Prioritize waste recovery

- Adopt technological processes that offer the least environmental impact

ISO 14001 / UNI EN ISO

14001:2015

FSC™ CHAIN

OF CUSTODY

PEFC

ISO 14001 / UNI EN ISO 14001:2015

FSC™ CHAIN OF CUSTODY